If the machine simulates the actions of people, then the tools determine the meaning of the actions.

Everyone must have seen many different kinds of brush products in life.

In fact, in industry, brushes are also working hard in different fields. Today, let us enumerate how industrial brushes work in different environments!

Mechanical parts-absolute assistant in manufacturing

Industrial brushes are commonly used in the production of various mechanical parts. For example, industrial brushes are used in engine production to remove burrs on the surface of parts.

The material of the industrial brushes that usually appear in the production lines of metal products such as steel products and copper products is generally relatively special. Because what is needed at the moment is that the brush can adapt to the special environment in which the parts are produced, such as high temperature, corrosion, acid and alkali, and so on.

Furthermore, in order to be able to adapt to the high-strength working environment, brushes with a relatively hard texture are also selected, such as adding special materials (steel wire) to nylon to make the brushes hard and not easily damaged.

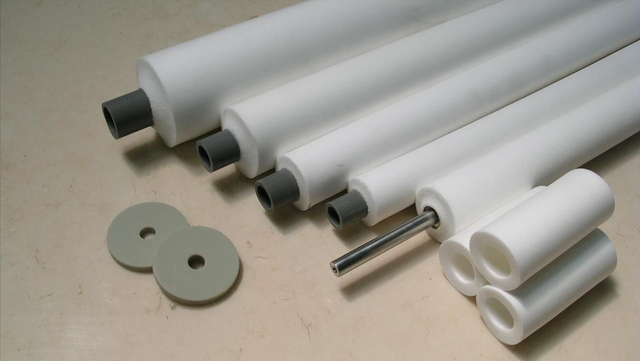

The brush products used in the industry include iron brushes, tube brushes, nylon polishing brushes, polishing brushes of other materials, roller brushes, steel wire brush rollers, spring brush rollers, grinding wire brush rollers, etc.

Glass products-the clean guarantee of precision instruments

Generally, the glass products produced by glass factories need to be cleaned before leaving the factory, such as some chemical test tubes, plastic bottles, glass bottles, wine bottles and so on.

At this time, most manufacturers choose industrial brushes made of nylon wool because of their high softness, good recovery, and wear resistance, which can better clean and protect them during operation.

However, it should be noted that professional industrial brushes are customized according to the size and shape of test tubes and glass bottles, which will be more convenient for cleaning.

The brush products used in the industry include cleaning brush rollers, side brushes, PP, PU, PVC, PVA absorbent sponge rollers.

Textile production-indispensable for processing operations

In textile production and printing and dyeing industry, the selected industrial brushes are different from the two mentioned above.

Because textile fabrics and silk satin are relatively fragile materials, the softness of the wool is very high during operation, and it cannot cause damage to the surface. The textile production is from the front end to the back end, all the way from simple samples to detailed finished products. , Need a lot of brush tools in countless work links.

It can be said that the textile processing industry has always been a large user of industrial brushes.

The brush products used in the industry include stereotyped brush wheels, tooth brushing machines, bristle brushes, combing brushes, brown brushes, rotating brushes, microcrystalline abrasive brushes and polishing cloth wheels.

We respond wisely to the past challenges, and we are ready for future opportunities.

Many industrial brush companies have used cash, technology and innovative spirit to open up more and more extensive roads, and at the same time actively expand the role of the market with the goal of product upgrades.

In the same field of competition with international competitors, my country's industrial brush industry has given full play to its strong advantages and strives to occupy a place in the world.

Post time: Aug-10-2021